No two patients are the same. For this reason, anyone with a foot disorder or problem should undergo a biomechanical study to determine the idiosyncrasy of their gait and relate it with the rest of their body and personal characteristics, in order to detect possible pathologies and solutions provided by the use of custom functional insoles.

Only then is it possible to make up a personalised prescription and collect the data (3D scanning or mould) to develop a custom functional insole according to the characteristics of the patient. The main elements in the prescription are the kind of material to use and the biomechanical treatment with the required corrections.

Experts in 3D design and production of fully customisable, functional insoles

At Biomech Consulting, we are experts in the 3D design and production of fully customisable, functional insoles and, based on our track record and experience, we can guarantee and testify to the value and use of foot orthoses for enhancing a patient’s foot health and well-being.

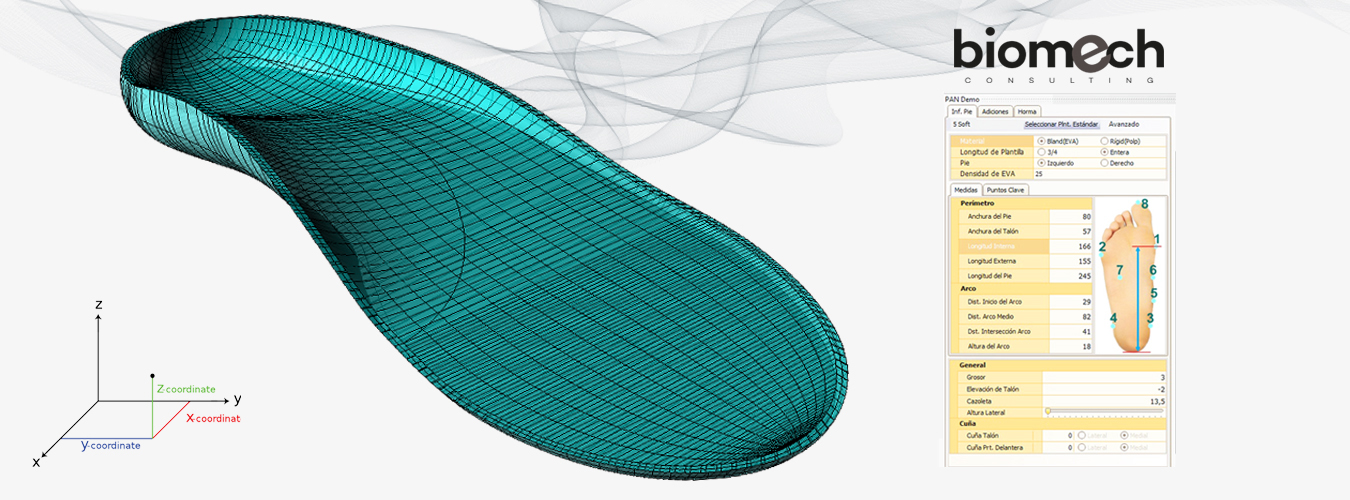

Every foot orthosis that we make begins with a biomechanical study performed by a podiatrist and a mould is taken or a 3D scan performed of the patient’s foot. These data culminate in a prescription that is used in the 3D design with our own state-of-the-art CAD programme.

Although the price of functional foot orthoses produced with 3D technology is higher than standard insoles, it goes without saying that this is more than justified due to the quality of the treatment, the safety of all the anthropometric measurements of all of the insole’s parts or corrections, the accuracy when producing a second pair, the materials used and the excellent results obtained in terms of patient health. Firstly, we have to be aware that generic insoles are not a healthcare product and do not, therefore, treat a specific pathology; unlike custom insoles, which are prescribed by a podiatrist and designed to correct each patient’s condition.

- The key element differentiating the custom insoles of Biomech Consulting from standard insoles is that they are produced from a 3D model of both feet. Every patient is different and their two feet are not the same either. For the data collection, we use the latest 3D scanning technology, the Biomech Scan 100, developed by the Valencian Biomechanics Institute exclusively for Biomech Consulting.

- When a foot clinic has a prescription and mould or scan corresponding to the feet of a patient, they can work with the help of Biomech Consulting. Worthwhile synergies can be developed since we boast a valuable team of experts in biomechanics, podology and podiatry, 3D design, numerical control machining and digital data collection. Our B2B system is a way of offering patients excellent results by means of cooperation between the foot clinic treating the patient that elaborates the prescription and mould or scan and the Biomech Consulting team. We develop the final product based on the needs of the patient prescribed by the podiatrist using machined materials finished to the highest quality. What’s more, a wide range of materials are available such as single-, double-, or triple-hardness EVA, polypropylene (natural and with carbon) and polyurethane.

- At Biomech Consulting we also personalise the finishing materials as we have a wide range of colours and thicknesses.

- Your feet support your body. And what’s more, each foot has 26 bones, 36 joints and over 100 muscles, tendons and ligaments, not to mention 7,000 nerve endings. Given their importance, it is necessary to make patients aware that using generic insoles without a medical prescription is not enough.

- In the case of sportsmen and women, using custom insoles prevents injuries, improves sports performance, provides more stability, reduces muscle fatigue, gives more cushioning and stops toe deformities, calluses and corns from developing.

- Biomech Consulting makes the mechanical additions and corrections required for any kind of orthosis according to the pathology of the patient.

- It is possible to combine up to three hardnesses in the same machined orthosis. In other words, we are able to give one single insole different levels of hardness. Biomech Consulting guarantees the highest level of correction with a high Shore A EVA, but we also offer maximum comfort and plantar pressure distribution with another material, namely polyurethane.

- Thanks to the internal know-how of our systems and staff, Biomech Consulting’s custom functional insoles provide sportsmen and women, elderly patients, children, diabetic patients or any other patients with the correct distribution of plantar pressure and the right balance of pronation-supination moments, all of which is necessary for eliminating the symptoms of any pathology.

- It is worth highlighting that Biomech Consulting is also the pioneer in polyurethane machining. Our team is the first Spanish company to succeed in machining this material to obtain unique, fully customised insoles with unbeatable features. Polyurethane is particularly useful for the treatment of pathologies such as diabetic foot. However, as we have mentioned, it is not the only material we work with. Thanks to our experience and the high level of technology at our disposal, where our comprehensive, advanced design system assisted by CAD-CAM software and our working technology based on a philosophy of ongoing improvements come into play, we have the control and the means to work with the material that adapts best to each particular case.

For all these reasons, we can conclude that we have all the materials, professionals, premises and services required to guarantee the best possible final outcome. It is a unique product, capable of meeting the needs of any medical case, which is very important if we take into consideration that there as many kinds or orthoses as there are patients.

And to wind up, it is worth mentioning that the most advisable thing to do is to choose insoles produced exclusively for each patient because we are convinced that they can improve their quality of life in the vast majority of cases.

We hope you have found this post of interest. At Biomech Consulting, we’d be delighted to provide you with any information you may need. Please contact us via our website biomechconsulting.com or write to us at info@devbmconsultin.wpengine.com.

22/11/2022

22/11/2022