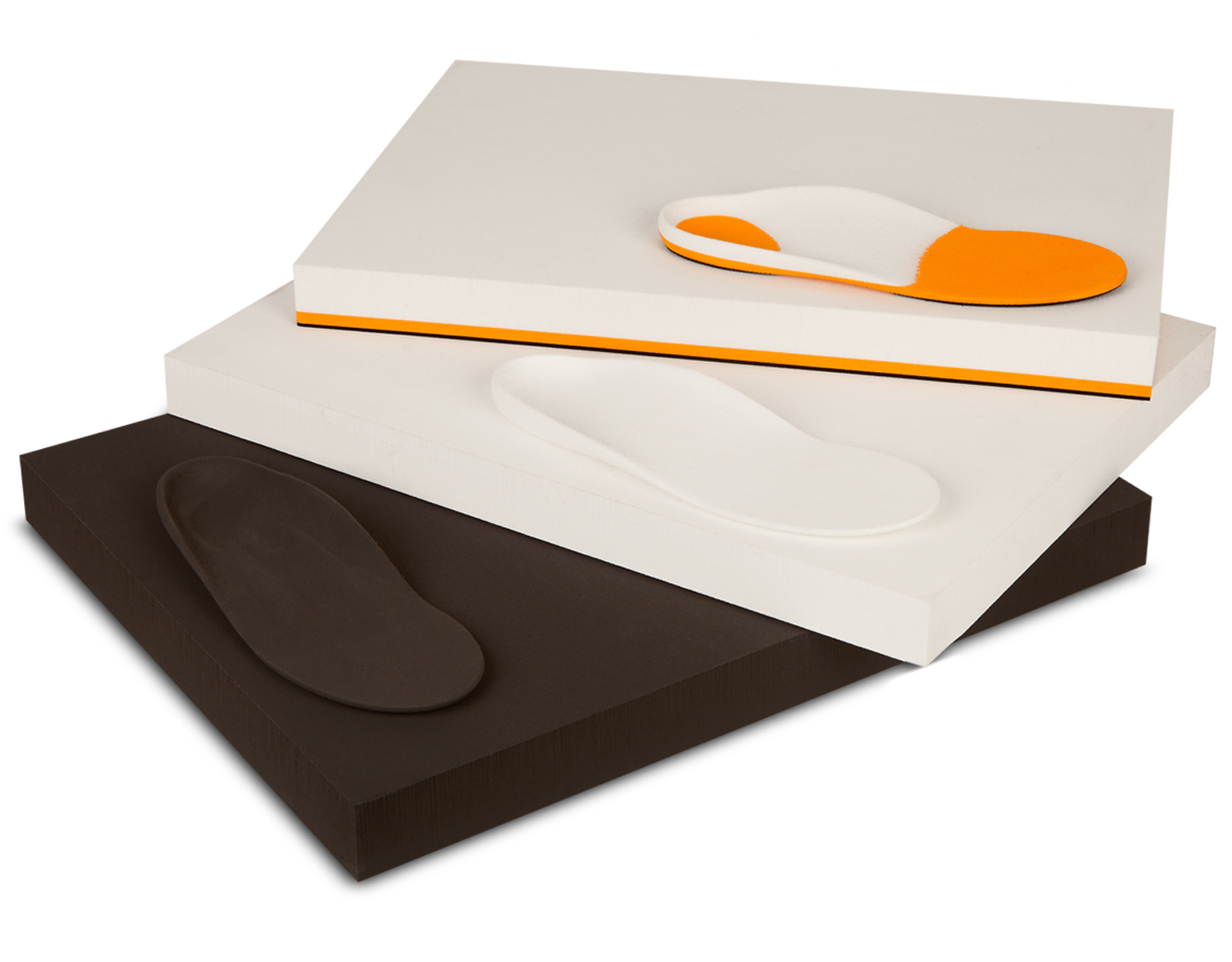

In the field of foot orthopaedics, 3D manufacturing systems are the latest and most accurate option for a completely bespoke treatment.

Machined (CAD CAM systems), functional 3D insoles are the answer to a wide variety of foot pathologies. The success of this kind of treatment depends on personalisation, the insoles being adapted to the feet and the pathology of each patient, in addition to the quality of the materials and their implementation.

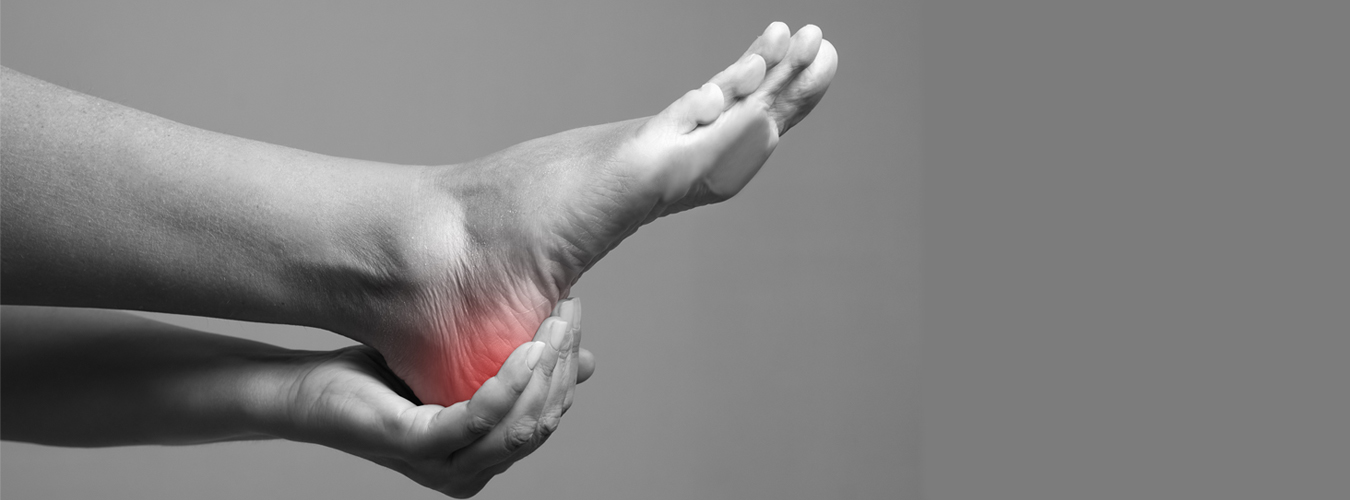

A biomechanical study aims to determine the patient’s pathology as well as its origin. It is vital that this study ends with a detailed prescription, which provides us with the necessary guidelines to create an insole that is healthy and beneficial to the patient.

Along with the correct distribution of plantar pressure, another requisite of a machined, functional 3D insole is to produce the right balance between the pronation and/or supination moments of the foot so the musculoskeletal system does not need to make any compensatory movements and forces or rotations beyond those that are normal.

For this to occur, it is essential to take into account aspects such as the patient’s weight, height, level of activity, etc. and to choose the material that best meets their needs, considering variables such as stiffness, recovery and the percentage of compression of the material to be able to offer a product that provides each patient with the perfect balance to improve their quality of life and painful pathology, while ensuring that the therapeutic properties of the foot orthoses are long-lasting.

The types of foot orthoses can be classified according to the five biggest groups of users or patients: children, the elderly, sportsmen and women, women with characteristic foot problems, and people with special pathologies such as diabetes; however, in fact, there are as many types of orthoses as there are patients.

A biomechanical examination, a podiatrist’s prescription, a mould-taking and/or scan of the foot, and a high-quality laboratory are essential requirements for insoles to perfectly fit the needs of each individual.

Browsing our website will show you the details of the way we work and what Biomech Consulting understands by foot orthoses from the perspective of health, biomechanics and scientific proof.