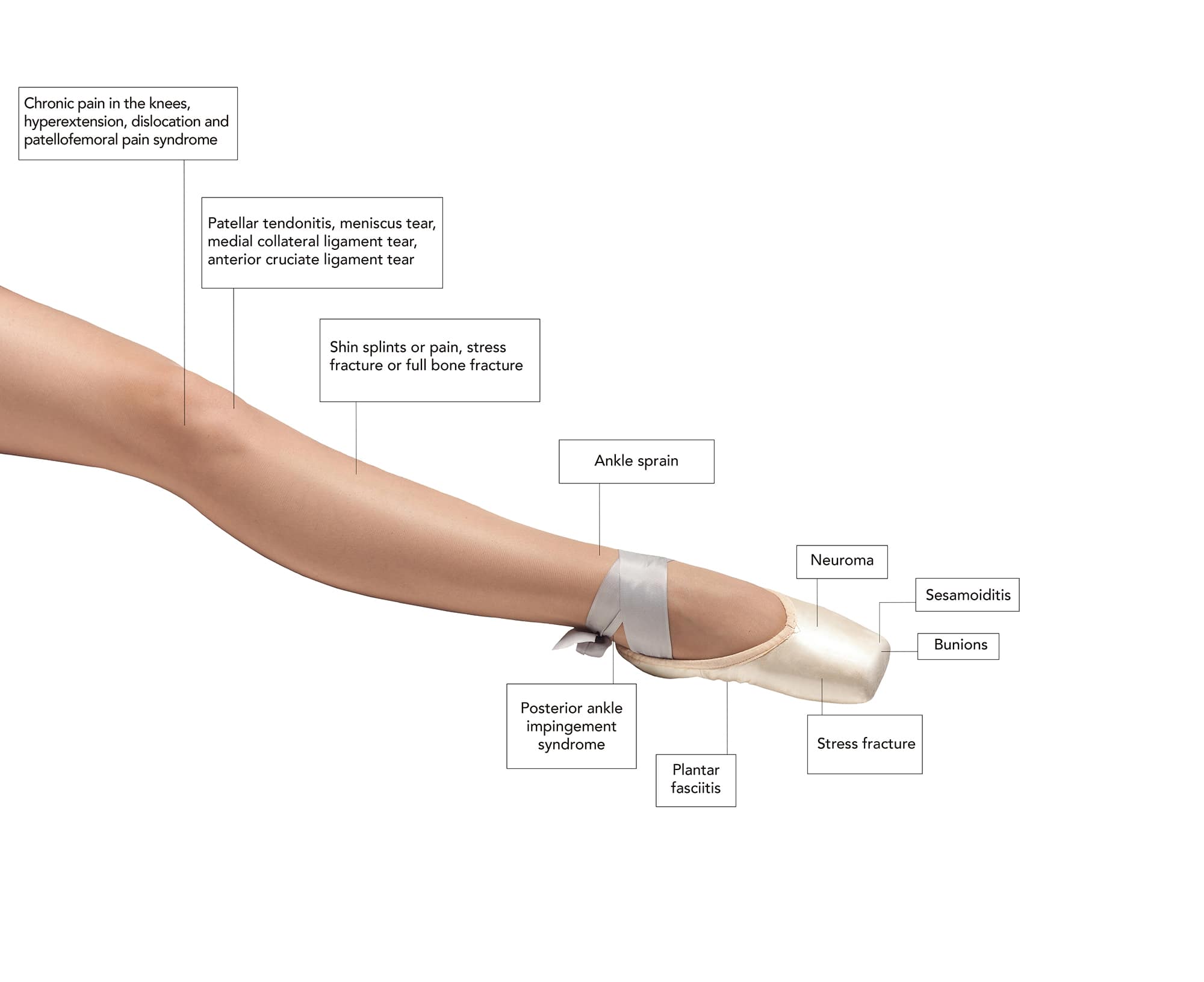

Each of our insoles aims to control, treat, alleviate or offset an injury or deficiency. As this is a health product, quality and safety are necessary conditions.

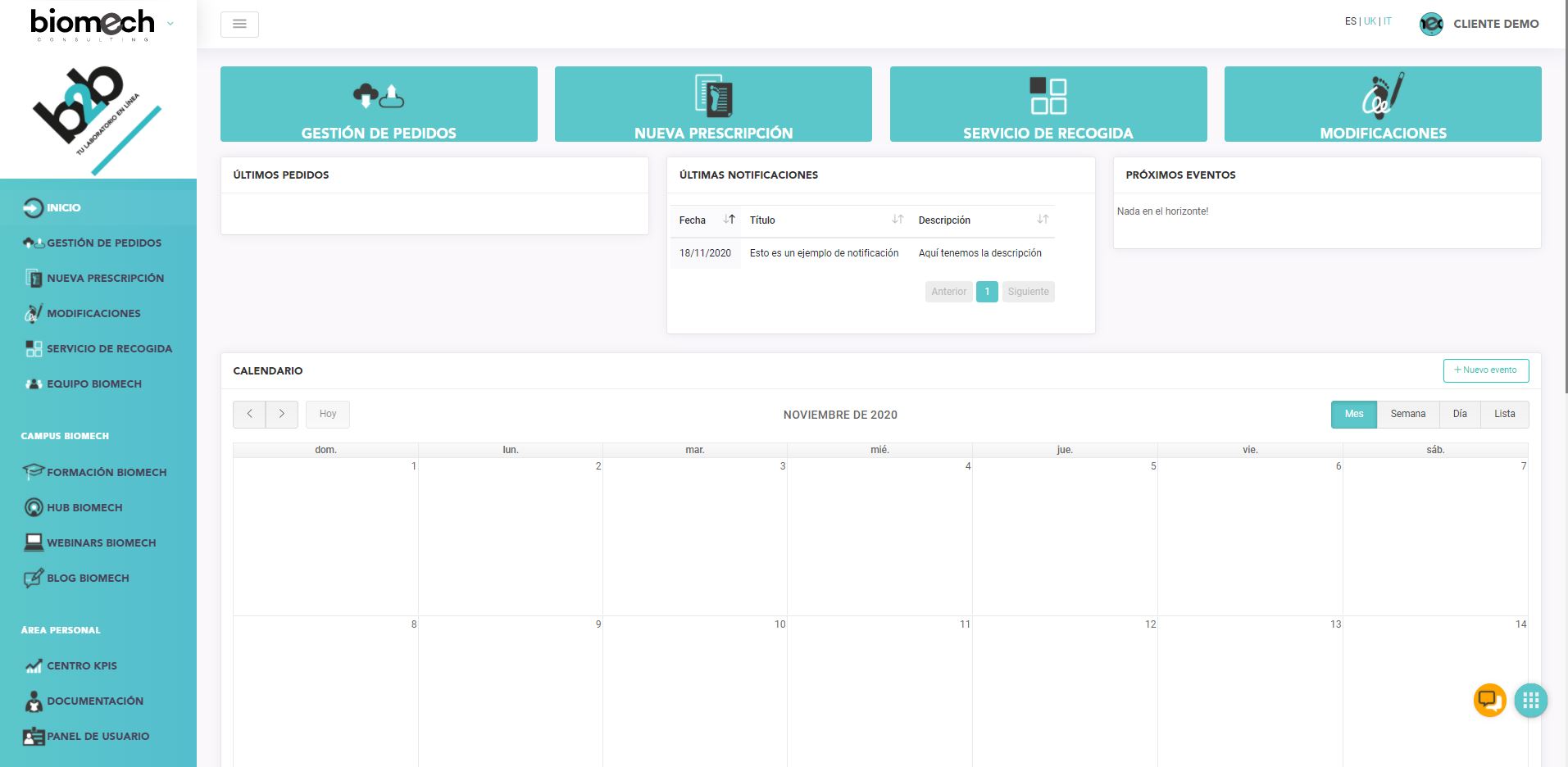

At BIOMECH CONSULTING we guarantee the quality and safety of each of our insoles because we continuously control, check and improve each phase in the production process, based on the standard ISO 9001.

The quality of our product largely depends on the raw materials we use. For this reason, we continuously research new materials that will allow us to develop more efficient, lighter and more comfortable products, and this is why we only collaborate with suppliers who comply with all the quality, hygiene and sustainability demands that give our INSOLES great added value, for the benefit of your patient.

We demand that our collaborators’ products are made in line with strict quality and safety standards, while they must also be supported by internationally recognised seals and compliant with legislation in force.

OEKO – TEX

STANDARD 100 by OEKO – TEX is the world-leading ecological label for textile products. Products that are produced under these standards are known for being products that have been assessed and certified by INTERNATIONALLY renowned institutes and, in addition, this certificate assures the consumer that the textile products have been analysed, controlling substances that are harmful to health, and producing them safely, responsibly and transparently.

INESCOP VEGAN

This certification by INESCOP guarantees that the main chemical nature of the material does not comprise fibres of animal origin (skin with fur, leather, silk, wool or down).

DERMATEST

A product certified by DERMATEST guarantees maximum efficacy and excellent skin tolerance, thus ensuring the safety of your patients.

SG PLUS CERTIFICATION

This is a guarantee of quality, hygiene and safety in the material, which does not cause allergies or contain harmful substances that are a risk to the health of the distributor, handler or patient.

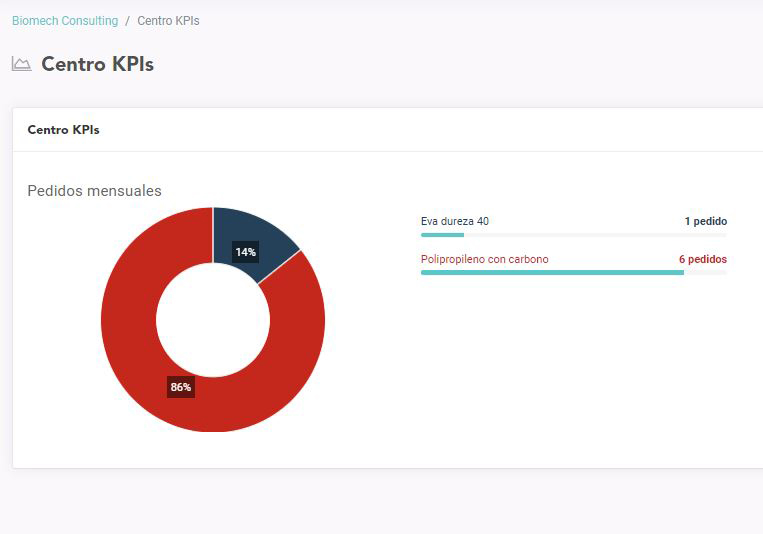

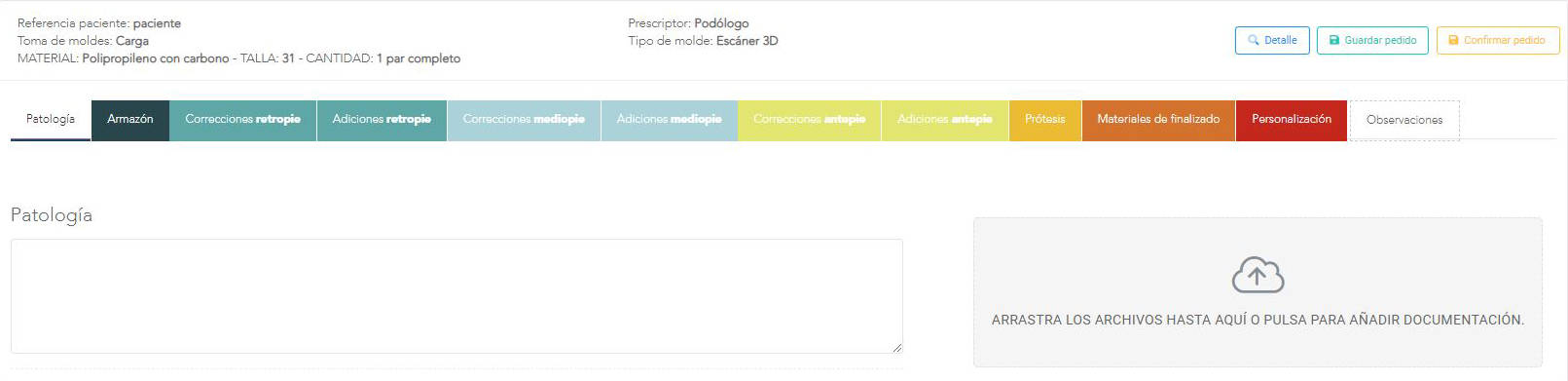

At present, we have all the machinable materials on the market: natural polypropylene, carbon-fibre polypropylene, double- and triple-stiffness EVA, polyurethane, etc. Numerous finish options and corrections make our product the right solution for your patients while also offering you distinctive value over your direct competitors.

You can consult the variety and qualities of our materials in our DEFINITIVE GUIDE TO MATERIALS FOR ORTHOTICS.

If you have any questions about which materials are most suitable, you can always contact the expert podiatry team at Biomech Consulting by filling in our form https://biomechconsulting.com/contacto/ or writing to us at info@devbmconsultin.wpengine.com